Written By: Dravvt

Topics Covered:

- Types of Drawings

- Technical Drawings

- Floor Plans - 2D

- Elevation Views - 2D

- Cross Sections - 2D

- Normal Projections - 2D

- Projections - 3D

- Sections - 3D

- Axonometry - 3D

- Technical CAD Drawing - 2D

- Explosion View - 3D

- The Construction Process

- Requirement Specification (Preparation Phase)

- Concept Development (Creative Phase)

- Schematic Construction (Analytical Phase)

- Detailed Construction (Technical Phase)

- Final Manufacturing Drawings (Documentation and production Phase)

- Drawing and Sketching Process on the Computer with Software (Digital Phase)

- Documentation and Management of Drawings (End Phase)

- Autodesk Software

Types of Drawings

Technical drawing is far more than just a skill; it's an essential part of the creative and problem-solving process. It serves as the bridge between ideas and their real-world implementation, from conveying complex concepts to streamlining construction processes. These drawings are the backbone of documentation in contracts, construction, and manufacturing. Their primary role is to communicate the designer's vision with precision, ensuring that every aspect of a design—from size to materials—is faithfully represented for production, assembly, and construction.

While artistic drawings can range from freeform styles like Zentangle to lifelike realism, technical drawings are much more focused and precise. These drawings are typically two-dimensional representations that specify everything from size and shape to material details, and even how the object interacts with others. Unlike art, which can evoke interpretation and personal meaning, technical drawings have a single, unambiguous purpose: to provide a clear, direct representation that ensures no room for misunderstanding, making it an indispensable tool in construction and manufacturing.

Technical drawing professionals, also known as technical draftsmen or illustrators, are highly trained individuals who specialize in crafting precise and intricate designs for a variety of industries, including engineering, architecture, and manufacturing. These experts possess the ability to turn abstract ideas into detailed visual representations with incredible accuracy. For engineers and architects, the ability to quickly sketch ideas by hand is critical, as these initial sketches form the foundation for more detailed drawings. Hand sketching remains a vital skill in the technical drawing field, even in a world dominated by advanced software.

There is no one-size-fits-all in technical drawing; different types are used for different purposes. Whether it's plans, elevations, sections, or isometric drawings, each serves a unique role in communicating a specific aspect of the design. For instance, assembly drawings guide the step-by-step process of putting components together, while wiring diagrams show how systems interconnect. Mastery of these various types of drawings is crucial for professionals in fields like engineering, architecture, and industrial design, as they form the blueprint for creating tangible, functional products and structures.

Read more: Mastering Technical Drawings A Complete Guide to Projection Types And Design Principles

By Galileo Galilei - Unknown source, Public Domain, https://commons.wikimedia.org/w/index.php?curid=238890

Technical Drawings

Technical drawings are the universal language of design, providing precise blueprints for creating objects or structures. Also known as mechanical or dimensioned drawings, they are essential tools in engineering, architecture, and manufacturing, capturing details like size, shape, and materials to ensure clear communication of design intent.

Final production drawings translate design concepts into reality, specifying exact measurements and materials to guide the manufacturing process accurately. Without these detailed instructions, building a design as intended would be nearly impossible.

From towering skyscrapers to intricate machinery, technical drawings bridge the gap between ideas and physical products. They come in many forms, each serving a unique purpose—2D orthogonal projections, sections, cutaways, 3D axonometric views, isometric drawings, exploded views, and more.

In the next sections, we’ll dive into these categories, exploring the world of sections, 3D axonometry, CAD technical drawings, 2D layouts, and beyond.

By Bundesarchiv, B 145 Bild-F038800-0010 / Schaack, Lothar / CC-BY-SA 3.0, CC BY-SA 3.0 de, https://commons.wikimedia.org/w/index.php?curid=5455712

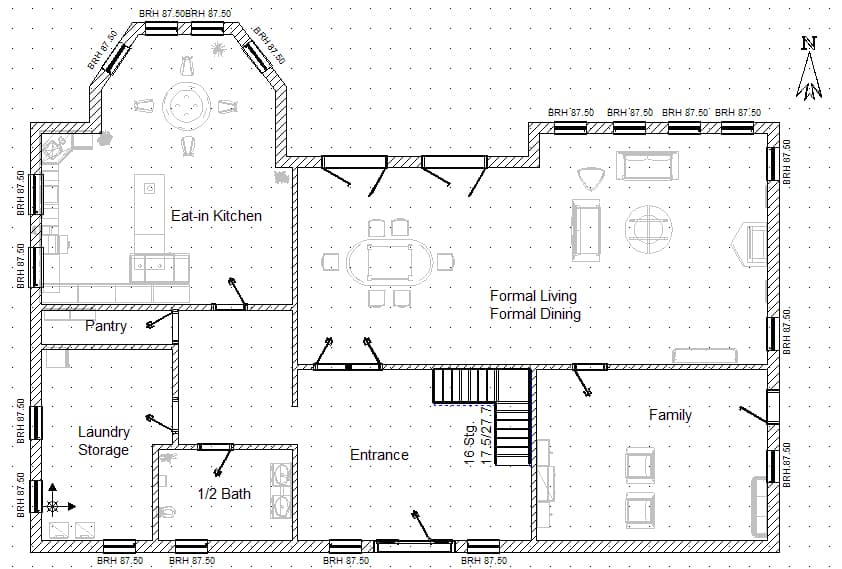

Floor Plans - 2D

In a top-down view or floor plan, the observer looks at an object, a building, or an entire site from above. This type of drawing provides a clear and detailed representation of the layout of a space, showing the arrangement of rooms, doors, windows, and other elements such as furniture or fixtures. It is one of the most common types of technical drawings used in architecture, construction, and interior design. The purpose of a floor plan is to give a precise idea of the spatial relationships and dimensions within a space.

Floor plans are created in two dimensions, typically without any perspective. This means that the vertical elements (like walls) are shown as they would appear from above, often using simple lines to represent the outline of the building or structure. The most common way to represent a floor plan is by using a scale, which helps to ensure that the dimensions are accurate and proportional to the actual size of the building or area.

For architects and designers, floor plans are crucial in the design process. They help visualize how people will move through the space and interact with its features. A well-designed floor plan considers not only aesthetics but also functionality, ensuring that the space is practical and efficient. It serves as a guide for construction teams to understand how to lay out rooms, corridors, and other features in accordance with the designer’s vision.

Besides its use in buildings, a floor plan can also be used for larger areas such as outdoor spaces, landscapes, or even cities. These larger plans show how different sections of a site are organized and connected, and they often include details like roads, pathways, and landscaping elements. Whether for a home, office, or complex project, a 2D floor plan remains an essential tool for visualizing and planning spaces efficiently and effectively.

By Boereck - A personal created drawing, Public Domain, https://commons.wikimedia.org/w/index.php?curid=650237

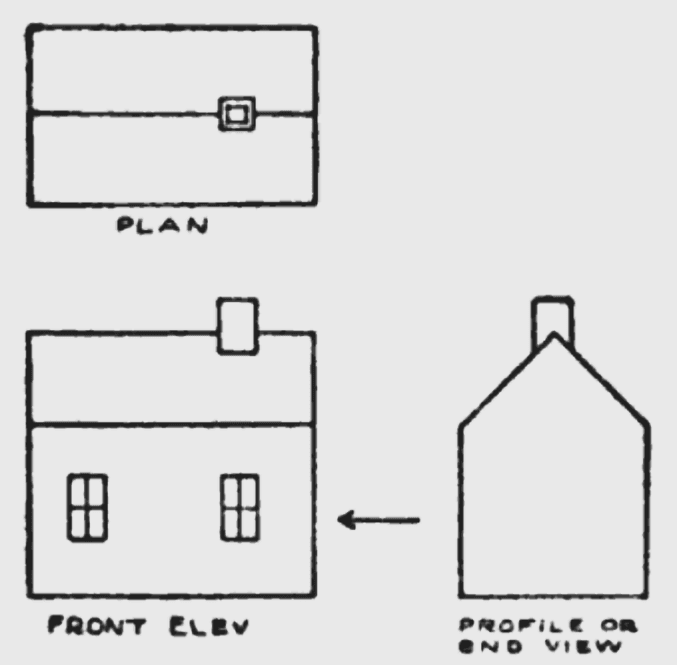

Elevation Views - 2D

An elevation, or side view, displays one side of an object or building, providing a 2D representation of its exterior from a particular perspective. This type of drawing shows the vertical features of a structure or object, often including the facade, windows, doors, and other elements that define its appearance. The purpose of an elevation is to give a clear understanding of the external view, without the complexity of perspective, offering a straightforward depiction of the object's shape.

In a 2D elevation, the front, side, or rear view of a building or object is shown as it would appear if seen from directly in front of or to the side of the object. Unlike floor plans, which provide a layout of the interior, elevations are primarily focused on the exterior, highlighting architectural features. This type of drawing is commonly used in architecture, engineering, and design to communicate the appearance of buildings, facades, and other structural elements.

While an elevation provides a general view of a structure or object, it does not include measurements or intricate details such as the depth or three-dimensional relationships. It is more about showing the outline and major elements of the exterior, allowing the viewer to understand how the building or object appears from a specific angle. For detailed construction purposes, additional drawings or sections would be needed to convey specific dimensions and internal features.

An elevation drawing is a vital tool for designers and architects, helping them visualize the vertical aspects of their designs. It plays an important role in both the early design stages and the final presentation to clients, contractors, or other stakeholders. Elevations can also be used to assess the aesthetic aspects of a building or object, ensuring the desired visual impact and harmony with surrounding elements.

By William A. Radford, Ervin Kenison - https://books.google.com/books?id=niJGAQAAMAAJ&pg=PA66, Public Domain, https://commons.wikimedia.org/w/index.php?curid=138698796

Cross Sections - 2D

A 2D cross section is a drawing that represents a slice of an object or building, revealing its internal structure and features as if it had been cut through. This type of drawing is used to show the interior details that would not be visible from the exterior, such as the arrangement of components or the layout of a space. The cross-section typically highlights how different parts of the object or structure relate to each other in a vertical plane.

In a typical cross-sectional drawing, a thick, dark line is used to indicate the cut, often with arrows at each end to show the direction of view. These arrows indicate from which perspective the section is being viewed, providing the viewer with clarity regarding the orientation of the slice. The section line itself is also important for understanding the specific location of the cut in relation to the entire object or building.

Unlike external views such as floor plans or elevations, a cross section reveals the interior workings and layers of an object or structure. This allows designers, engineers, and architects to examine the internal details, including materials, thicknesses, and connections between different elements. It also helps visualize how various systems, such as plumbing or electrical installations, are integrated within the design.

2D cross sections are essential in both the design and construction phases. They provide the level of detail needed to accurately convey the inner workings of a building or object. By showing hidden elements and relationships, these drawings are indispensable for understanding how a design functions as a whole and ensuring that all components fit together correctly during construction.

Von DieDINsagt - Eigenes Werk, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=76411301

Normal Projections - 2D

In a 2D normal projection, the object is represented from different angles, where each view is projected onto an imaginary plane parallel to the sides of the object. This technique provides a clear and accurate representation of the object without the complexity of perspective, ensuring that the shape and features are depicted in a straightforward manner.

When using this method, the observer is imagined to be looking straight at one side of the object. Each of the 2D projections represents what the observer would see from that perspective. By showing the object from multiple viewpoints, the technique allows for a more complete understanding of its geometry, which is essential in technical illustrations.

Normal projections are essential for creating technical drawings as they provide precise and consistent views of the object. Unlike perspective drawings, which distort the shapes based on the viewpoint, normal projections maintain true proportions and angles. This consistency is crucial for design, manufacturing, and construction processes, where accuracy is key.

A drawing in multiple views typically includes the front view, top view, and side view. These views together offer a comprehensive understanding of the object’s shape and size. For more complex designs, additional views may be added to show other sides or interior details, making the drawing more informative and easier to interpret for engineers, designers, and manufacturers.

Von Original: Iseeaboar Vektor: Biezl - Eigenes Werk, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=7402156

Projections - 3D

In a 2D drawing, multiple views would be required to represent all aspects of an object. However, using 3D projections provides a more efficient way to capture and display all components of an object in a single view. This technique saves drawing time and space on the drawing sheet, as it allows for a comprehensive representation without the need for additional views.

A 3D projection provides more information than just a front or side view because it shows the object in three dimensions, capturing depth, width, and height. This allows for a better understanding of the object’s shape and structure, providing all the necessary details in one view, which can be crucial for manufacturing or construction processes.

By utilizing 3D projections, designers and engineers can communicate complex shapes and forms more clearly. This is particularly useful when working with intricate parts or assemblies where it may be difficult to represent all aspects of the object using only 2D views. It ensures that the complete geometry is visible, reducing the risk of misinterpretation.

In addition to the obvious space and time-saving benefits, 3D projections make it easier to visualize the object as a whole. This is helpful not only for design and production but also for testing, assembly, and quality control. It ensures that all stakeholders can view the object in its entirety and understand how its parts fit together.

CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=783693

Sections - 3D

3D section drawings show how an object can be represented as a 3D cross-section, providing more information in a single view. By slicing through an object in specific areas, these drawings allow the designer to show internal components, material distributions, or complex internal features that are not visible in a regular exterior view.

This type of drawing is particularly useful for understanding how parts fit together and interact inside an object. It can be applied to mechanical components, buildings, and other complex systems, where seeing the internal structure is crucial for further design, assembly, or manufacturing steps.

3D sections provide a clearer, more detailed representation compared to traditional 2D section views, enabling more efficient decision-making and reducing potential errors during the manufacturing or assembly process.

Von Joshua Cesa, Alessandro Senno, Elia Venturini - Eigenes Werk, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=2737100

Axonometry - 3D

3D axonometric drawings display an object in three dimensions, where the angle between the baseline and the horizontal defines the view. Isometric drawings, for example, always have angles of 30° between the axes, which provides a clear, consistent method for showing depth, width, and height.

Dimetric drawings use two different angles, typically 7° and 42° from the horizontal, offering a slightly different perspective that can be helpful for certain designs. Trimetric projection, on the other hand, uses three scaled axes with three different angles, making it even more flexible for depicting complex structures.

Axonometric projections are valuable in technical drawings as they help to visualize the object in a way that preserves its proportionality, providing more detailed and accurate views for manufacturing or construction.

Von Petrus3743 - Eigenes Werk, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=59212857

Technical CAD Drawing - 2D

In 3D modeling, the object is initially constructed digitally, and then additional drawings are generated to ensure every component of an assembly is clearly identified. These drawings are essential for detailing parts, assemblies, and how components interact within the entire system.

Every 2D CAD (Computer-Aided Design) drawing is derived from a previously inputted 3D model, which ensures that all the dimensions, material specifications, and part relationships are accurately conveyed. This method allows for precise and efficient creation of technical documentation used in various stages of design, engineering, and production.

By relying on 2D CAD drawings, designers and engineers can streamline the creation of blueprints and technical plans, making it easier to collaborate, share information, and reduce mistakes during production or construction.

Image of 2d CAD drawing - By Wedrey - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=30053278

Explosion View - 3D

Have you ever wondered how a complex project like those from NASA or intricate engineering designs are presented? Behind every groundbreaking technological achievement or sophisticated machine lies an incredible amount of precision and attention to detail. The key to effectively communicating such designs often involves technical drawings, where the smallest details matter. Both 2D and 3D drawings can be created either by hand or using computer software. Hand-drawn sketches can range from freehand doodles to highly accurate illustrations made with precision tools. On the other hand, computer-generated drawings are often referred to as CAD (Computer-Aided Design) drawings.

In addition to CAD, other acronyms are often used in the context of technical drawings, such as CAE (Computer-Aided Engineering) and CAM (Computer-Aided Manufacturing). These drawings, especially when made with CAD, offer high precision and can be scaled accurately to specific dimensions. With the rise of 3D modeling programs, many drawings that once took designers a long time to complete manually can now be generated much more efficiently.

The exploded view is a visual representation technique commonly used in engineering, architecture, and industrial design. It involves displaying an object or assembly of components in such a way that the elements are spaced or separated from each other while maintaining their original spatial relationship. This representation allows for a detailed view of the internal structure of an object, showing how the parts fit together. It also helps in understanding the assembly and disassembly of complex products, such as machinery or electronic devices.

One of the main advantages of an exploded view is that it helps visualize how components of a product are assembled without the need to see the final assembled version. It is especially useful in creating instruction manuals and assembly guides, where it is important for the user to understand the arrangement and assembly sequence of the parts. By showing how each piece fits and connects, it also aids in identifying parts that may need replacement or maintenance.

This technique is not only used in engineering but also in fields like education and advertising. In education, exploded views allow students to better understand the principles behind complex structures or mechanisms. In advertising design, they can be used to create striking and detailed representations of products, highlighting their features and functions in a clear and attractive way.

Today, exploded views are primarily created using advanced 3D modeling software. These programs allow for the generation of precise and detailed representations of objects, making it easier to manipulate and view them from different angles. Exploded views can include annotations and labels to identify the parts, making them a useful tool for both designers and end users who need to understand how a product functions and is assembled.

Estimators and cost planners also rely heavily on technical drawings, especially when determining material quantities and sizes for cost estimation. This process is known as 'quantity takeoff.' Industrial standards provide technical drawers with clear guidelines on the required information and how it should be presented for clarity and accuracy.

By Д.Ильин, Duk, cmglee - Gear pump exploded.png, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=129280778

The Construction Process

As a general rule, the process begins with identifying a need, followed by developing ideas to address it. The process concludes when an idea is presented as the final solution, accompanied by technical drawings. In general, four to five phases in the construction process can be identified, which are used for scheduling and contract formulation. For more complex projects, such as robotics, each construction phase is subdivided into multiple subcategories. Often, additional steps in the analysis and testing process are necessary to find the best solution. This preparation is structured into six key categories, each playing a crucial role in ensuring the project's success, which are described below.

One fascinating aspect of the construction process is how multidisciplinary teams collaborate during the phases. From engineers and architects to designers and project managers, each expert contributes their specialized knowledge. In complex projects, such as the construction of space missions or robotic systems, communication between these teams is key to ensuring that every detail aligns with the final design.

Requirement Specification (Preparation Phase)

The assessment and definition of the need are the first steps in the construction process. In engineering, this document is often referred to as the project specification. Specifications include information about the budget, materials, colors, sizes, and performance criteria. As ideas begin to flow, referring back to the specifications helps narrow down the choices.

In addition to being a reference for budget and materials, a detailed specification also helps establish the project's environmental, social, and safety considerations. For example, building regulations in many countries require certain performance levels for sustainability and energy efficiency. For complex systems like robotics or aerospace engineering, these specifications might include performance under extreme conditions like temperature, pressure, or stress tests.

Concept Development (Creative Phase)

The next step for designers is to tackle the creative process of idea generation, typically starting with sketches rather than full drawings. This can involve more left- or right-brain activity, but it is most productive when both sides of the brain are engaged. Betty Edwards, in her classic *The New Drawing on the Right Side of the Brain* (2000), recommends spending quiet time alone to allow the thinking process to unfold. She states that "creative solutions to problems, whether personal or professional, become accessible through new ways of thinking and new ways of using the full power of the brain" (p. 6, translated by the author).

During this phase, ideation can sometimes extend into collaborative efforts. Teams may conduct brainstorming sessions, using diverse techniques such as mind mapping or lateral thinking, to approach problems from fresh perspectives. Concepts developed during this phase are typically rough, but they offer essential insights that guide the next steps toward a final design.

Schematic Construction (Analytical Phase)

Computer sketches can also be used at this stage. Clients can quickly respond to the ideas already thought through at this stage when drawings are provided that don't require detailed geometries.

If designers are skilled at sketching on a laptop or tablet, they can easily share their ideas with other team members, regardless of location. Hand or CAD drawings can be further developed into schematic drawings that explain future processes or assembly procedures.

At this stage, schematic designs often explore different configurations or layouts before committing to a detailed plan. In fields such as industrial design or architecture, these schematics may undergo several iterations, responding to client feedback and refining the design’s feasibility, aesthetics, and efficiency. In some cases, virtual prototypes or simulations are tested to validate the concept before progressing.

Detailed Construction (Technical Phase)

As the drawing progresses, more and more details are added. During the detailed construction phase, the project is further analyzed and optimized. This is the phase where geometry, dimensions, and specifics are worked out; this process can be time-consuming. Other components of detailed construction may include tests and the building of prototypes, often in an iterative process. 3D printers may also be used, enabling cost-effective prototype manufacturing for many products. "In the past decade, 3D models and 'Rapid Prototypes' have become a common method for conveying construction intent."

Detailed construction isn’t just about creating the final plans; it's also about refining and perfecting the design. A small tweak in dimensions or material can have a huge impact on performance. This phase often involves collaboration between various experts, such as material scientists and structural engineers, to ensure that the design will not only be feasible but optimized for durability and functionality.

Final Manufacturing Drawings (Documentation and production Phase)

These drawings, created by hand or using CAD software, are required to manufacture the final product. They provide all the necessary information and details to construct the product or complete a project. In other fields, these drawings may be referred to as installation or assembly drawings.

The creation of these final drawings can be a highly iterative process. Every detail is double-checked to ensure that no errors are made during manufacturing. In high-precision industries such as aerospace, automotive, or medical devices, even the smallest mistake in a manufacturing drawing can result in significant financial losses or safety concerns. Furthermore, advanced CAD software often includes features that simulate real-world conditions to test how designs might perform under stress or in extreme environments.

Drawing and Sketching Process on the Computer with Software (Digital Phase)

When it comes to computer-aided drawing, the construction process can look a bit different with 3D modeling. The concept phase still benefits from sketching (either by hand or on the computer), but advances to a preliminary CAD model and the Finite Element Method (FEM), an integrated analysis tool within CAD software. This can be an iterative process before the actual development and optimization phase, where the model is analyzed again with FEM. Iterations are easily handled with CAD modeling software.

The integration of FEM in CAD allows for more accurate simulations of how the model will behave under real-world conditions. This not only saves time but can significantly reduce the cost of physical prototyping. In fields such as aerospace engineering or civil engineering, these simulations can predict failures and avoid catastrophic errors in the real world, making this step crucial for the final design process.

Documentation and Management of Drawings (End Phase)

All drawings within a project, whether hand sketches, hand drawings, or CAD drawings, must be filed and managed. Companies typically use a document management system tailored to their needs for organizing and documenting their drawings. The International Organization for Standardization (ISO) provides standardized methods for document management in projects, including the uniform naming and cataloging of documents (International Organization for Standardization [ISO], n.d.-j).

Document management systems help ensure that drawings and revisions are tracked accurately. These systems allow companies to maintain a digital archive of all project files, making it easy to access and refer back to older versions of drawings. Furthermore, advanced document management systems are now incorporating artificial intelligence (AI) to automatically track changes and ensure compliance with industry standards, making the process more efficient and less prone to human error.

Autodesk Software

Autodesk, a software manufacturer, offers various CAD programs tailored to specific needs within different engineering fields. Students and trainees can gain access to Autodesk products and services (Autodesk, n.d.-a). Autodesk’s software offerings include:

+ Sketchbook for sketching,

+ AutoCAD as a widely-used CAD base program, and finally

+ Inventor® for professional 3D applications in mechanical design, documentation, and product simulation.

What makes Autodesk tools stand out is their comprehensive integration into multiple disciplines. Architects, engineers, and designers can all use Autodesk software to create a seamless workflow from initial concept sketches to final manufacturing drawings. Autodesk also continues to innovate with cloud collaboration tools, allowing multiple users to work on the same project in real-time, regardless of location.

For more information, visit the Autodesk website and explore their range of products and services.

Read more: Autodesk official website